- type Manual Putty

- accuracy 1 Micron

- colour Grey

- final consistency Semi-Flexible

- final hardness shore a 90 Shore A

- initial consistency Putty

- remarks Recommend for External Simple Forms

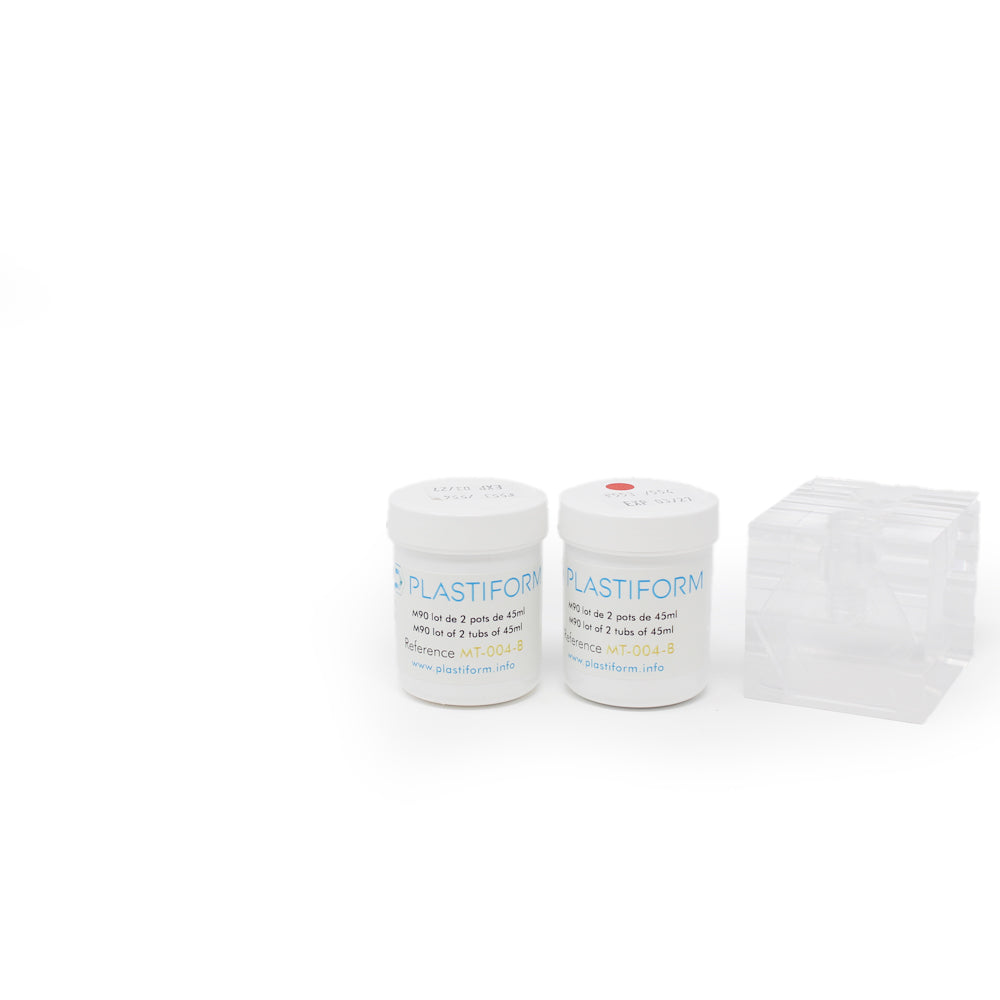

- working time 45 Seconds

- setting time 4 Mins (At 20 Degrees C)

- can it be cut Yes

- country of origin France

- brand Plastiform

- commodity code 39100000

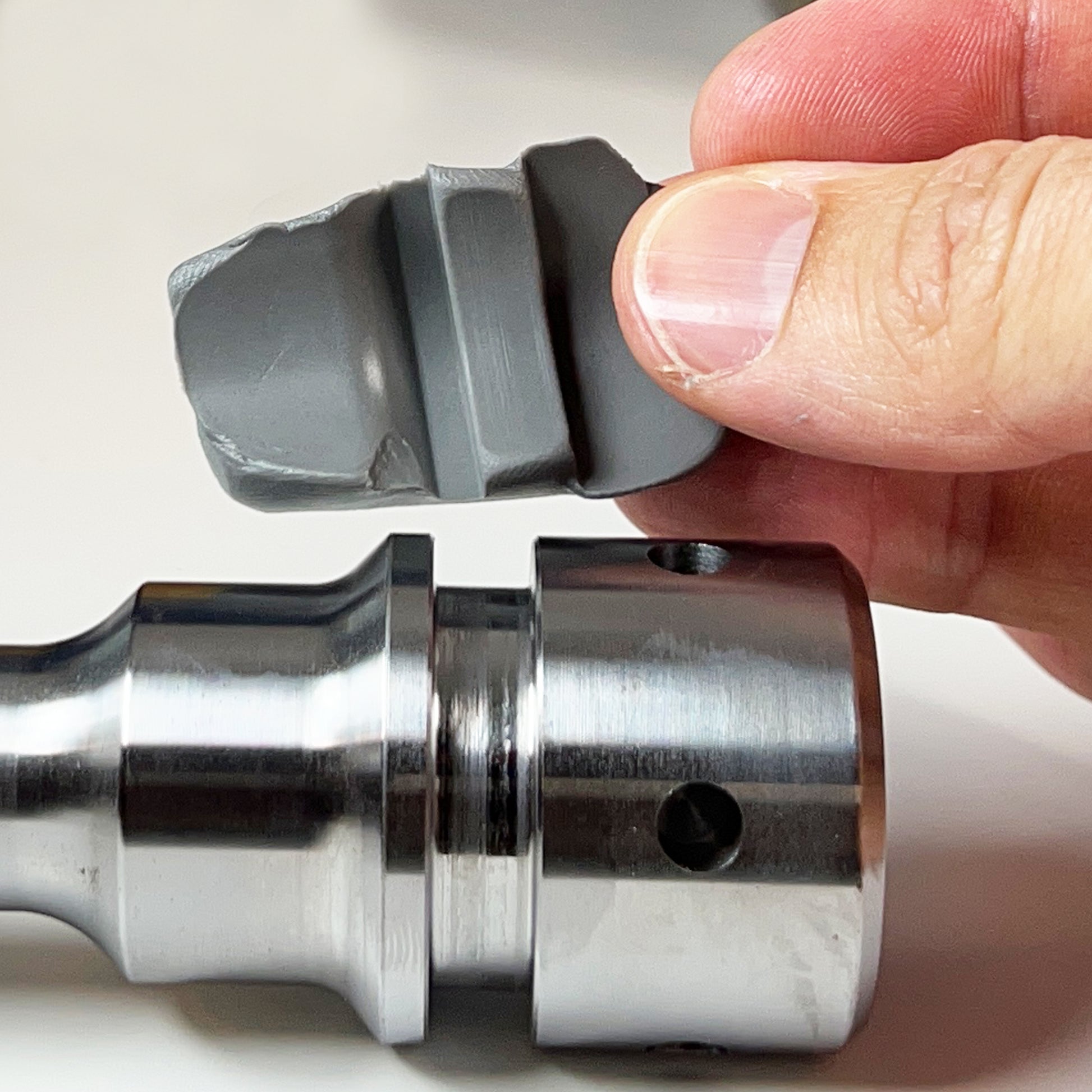

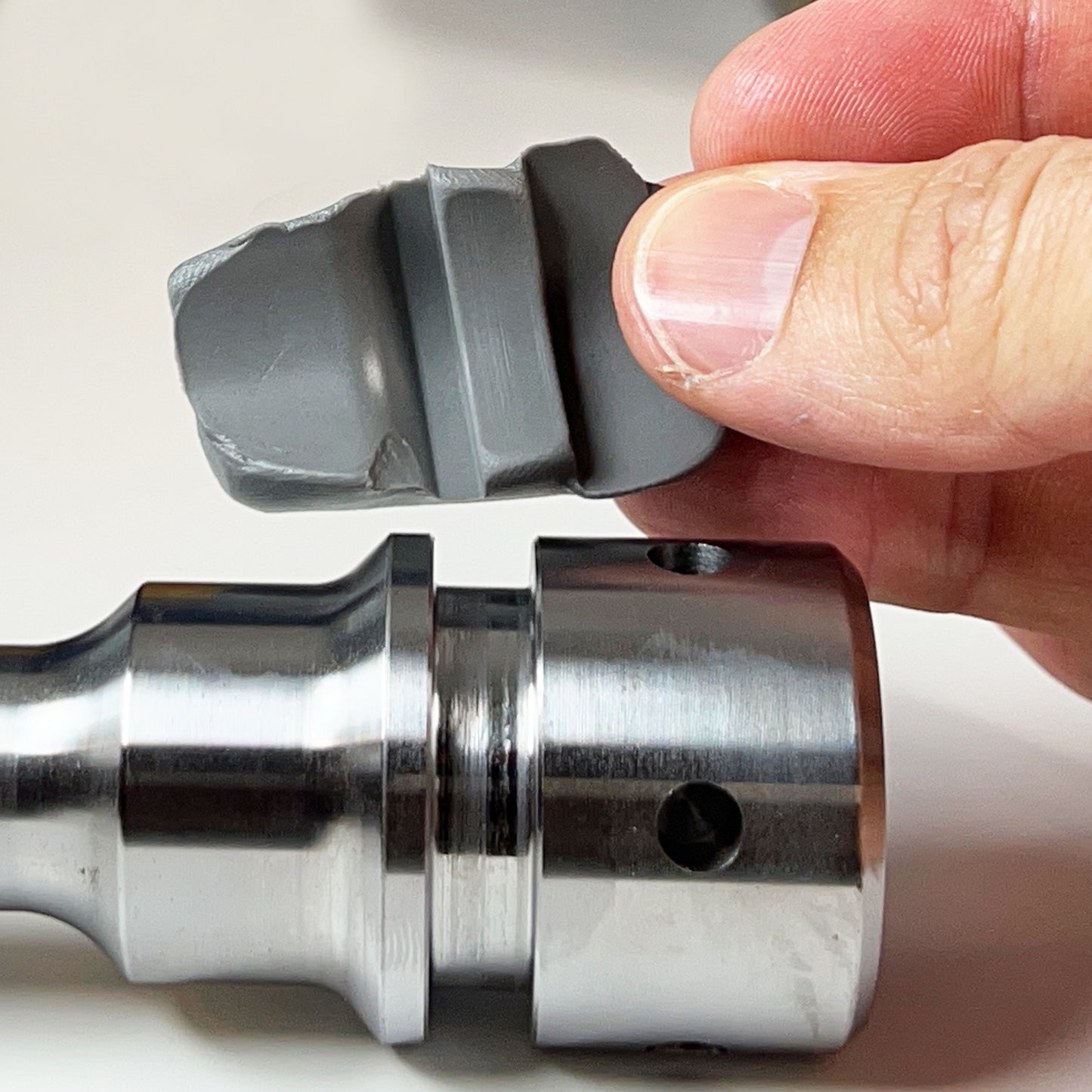

M90 is the only malleable product to become rigid after curing. The final impression has a hardness of 90 Shore A, which means that it is non-flexible and cannot deform when removed from the mold. This plastiform can only be used on simple shapes, without any Extraction Constraint.

The rigidity of the M90 allows it to be measurable with contact. This feature can be useful for repeated indicative checks that do not require micron accuracy. Its rigidity is also highly appreciated to protect fragile parts, it prevents vibration and resonance phenomena.

The M90 is recommended for creating rigid impressions of simple external shapes (threads, grooves, grooves, etc.). It is generally used on medium to large parts.